Automotive

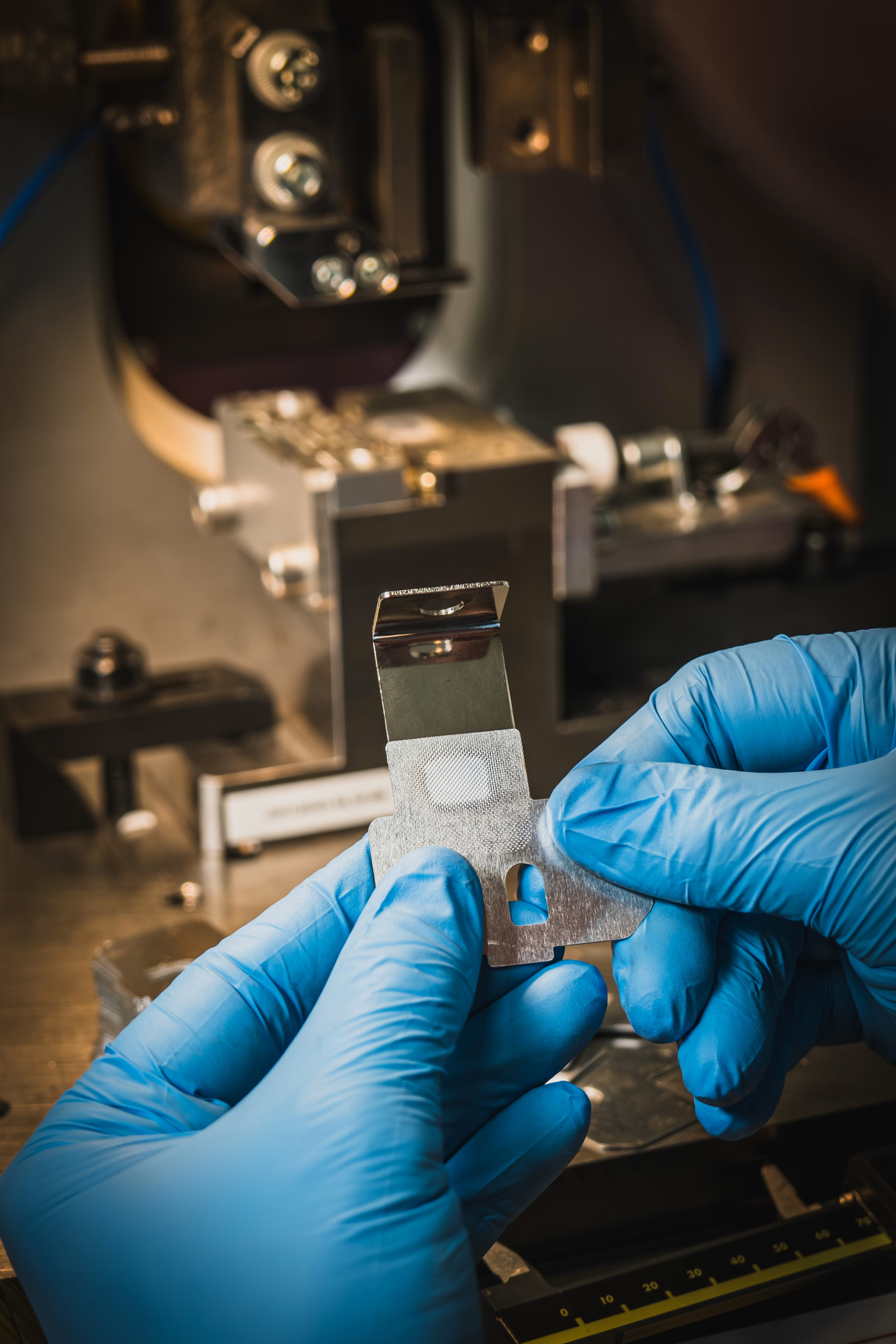

Battery

Medical

Food

Home appliances & furniture

Electronics

Making a difference with every connection: The impact of ultrasonic welding on the world

If I were to ask you, what does it take to save the world. Your answer would probably include some sort of monumental change. Sometimes the challenges we face may seem overwhelming, but you shouldn’t overlook the power of incremental progress.

We are here for you!

Ready to explore new opportunities? Contact us today to discuss your project requirements. Together, we can achieve precision, efficiency, and reliability in your manufacturing processes.

Follow us on social media: