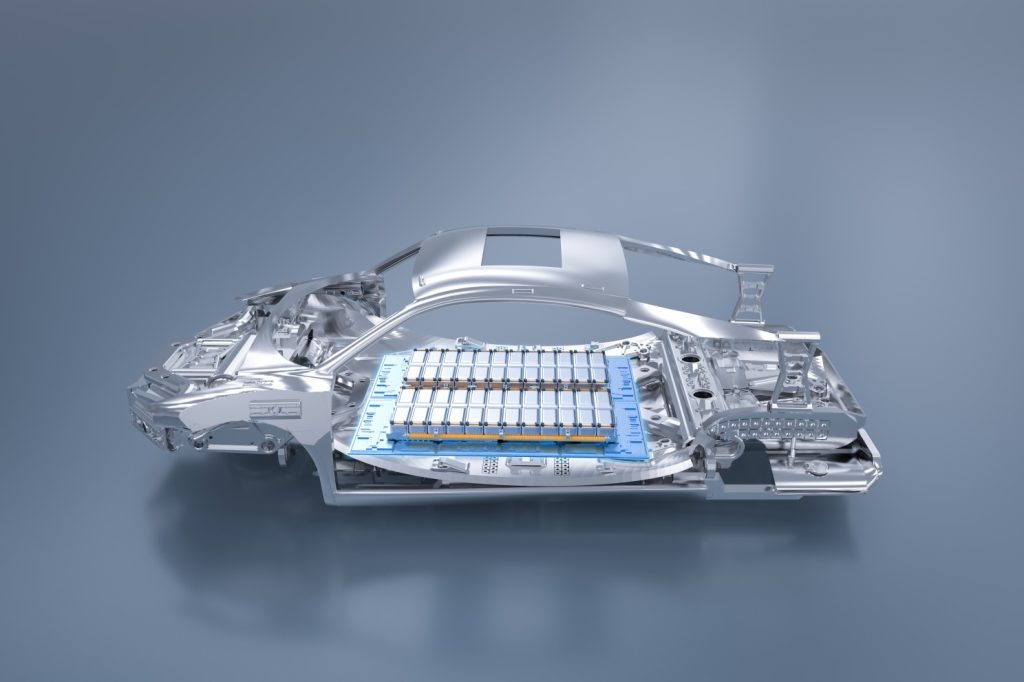

Battery manufacturing is at the heart of the global transition toward renewable energy and electrification. With the surging demand for electric vehicles (EVs), energy storage systems, and portable electronics, the need for efficient, precise, and scalable battery production processes has become critical. The complexity of producing high-performance batteries lies in ensuring safety, reliability, and cost-effectiveness while meeting ever-increasing production volumes.

Understanding Battery Manufacturing

The production of batteries is a multi-step process that requires exacting standards and advanced technologies to ensure quality and performance. At its core, battery manufacturing revolves around the creation of cells, which are then assembled into modules and, ultimately, battery packs.

Each step demands precision: from coating electrodes with active materials to ensure consistent energy storage to assembling delicate layers of separators and electrodes without damaging them. Welding is a critical process that ensures secure electrical connections, while automated systems manage the high-speed handling of fragile components. Finally, rigorous testing ensures that every battery meets safety and performance standards.

Manufacturers face the dual challenge of scaling production to meet soaring demand while maintaining strict quality controls—a balance that requires advanced automation and innovative manufacturing techniques.

How VIAL Automation’s Services Support Battery Manufacturing

In the battery manufacturing ecosystem, precision, repeatability, and scalability are key. VIAL Automation offers specialized services that enhance critical production processes:

Ultrasonic Welding for Terminal and Busbar Connections:

- Ultrasonic welding is widely used to join battery terminals to busbars in both cylindrical and prismatic cells.

- It creates robust, high-quality electrical connections without introducing additional materials like adhesives or solder.

- This process ensures low electrical resistance, critical for high-performance battery packs, while minimizing heat generation, which is vital for sensitive battery materials.

For our entire service stack for battery manufacturing and e-mobility. View our E-mobility prospect.

The Future of Battery Manufacturing

The battery industry is undergoing rapid transformation to meet the demands of electrification and sustainability. Trends such as solid-state batteries, advanced recycling methods, and the use of eco-friendly materials are shaping the future of manufacturing. To stay competitive, manufacturers must adopt agile and scalable production methods that reduce waste, enhance efficiency, and meet evolving safety and environmental standards.

Automation and advanced joining techniques, like ultrasonic welding, are set to play an even greater role as production scales and technologies advance. As batteries become more sophisticated, the need for precise, reliable, and repeatable manufacturing processes will only grow.

Why Choose VIAL Automation for Battery Manufacturing?

- Expertise in Ultrasonic Technology: A proven, industry-standard method for robust and reliable battery connections.

- Precision Automation: Ensures consistent quality and scalability for high-volume production.

- Commitment to Innovation: We stay ahead of industry trends to deliver future-ready solutions.

- Custom Solutions: Tailored to your production needs, minimizing downtime and maximizing efficiency.

Ready to power your production line with cutting-edge manufacturing solutions? Contact VIAL Automation today to learn how we can help optimize your battery manufacturing processes for performance and reliability.

We are here for you!

Ready to explore new opportunities? Contact us today to discuss your project requirements. Together, we can achieve precision, efficiency, and reliability in your manufacturing processes.

Follow us on social media: